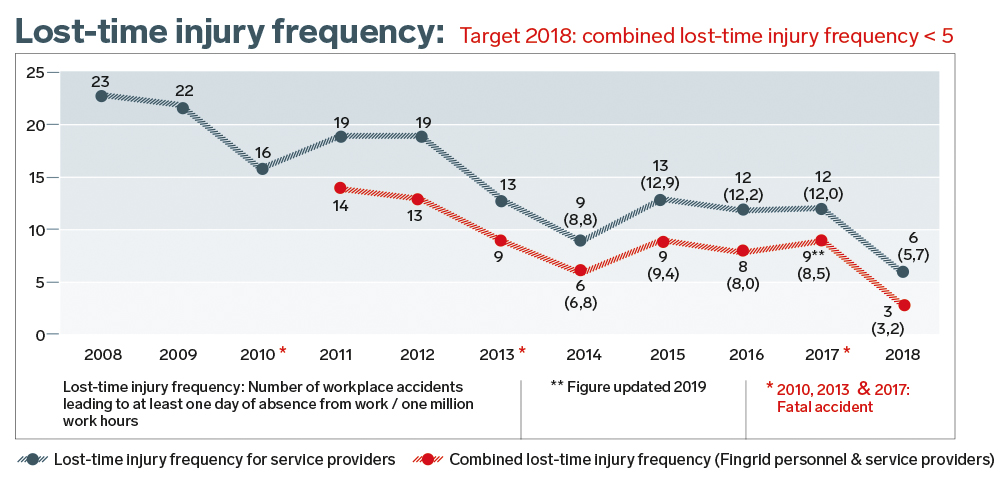

The combined lost-time injury frequency in 2018 was 3.2, and our target was to get below 5. It is especially noteworthy that we did not have a single serious workplace accident leading to more than 30 days of absence. The level of occupational safety has not improved all by itself, and a lot of work has gone into this achievement.

Four lost-time injuries occurred in 2018, two of which involved slipping or tripping. One employee suffered a wound on the arm during base casting and in March an employee fell from a height of 2–3 meters in conjunction with installation of an overhead ground wire. The employee was lifted into the air when the overhead ground wire detached from the excavator. A total of 12 occupational accidents occurred at Fingrid worksites in 2018, and they did not cause any absence from work.

700 dangerous situation notifications

Development of the occupational safety level at Fingrid worksites is also monitored by means of leading indicators that measure the amount of work done to promote occupational safety. These indicators show that we clearly improved our result in comparison to previous years. A record number of dangerous situation notifications were submitted: approximately 700 when the target was to obtain at least 400. Dangerous situation notifications include both safety observations and near miss notifications. It is positive that more than 500 of these were safety observations. Safety observations allow us to gain information about hidden risk factors and involve everyone in developing occupational safety.

About 120 of the dangerous situation notifications were near miss situations, 4 of which were classified in the most severe A category. Two of these were associated with equipment failures in high-voltage devices at substations. In one case, the operating voltage was connected to a transmission line too early while in the other construction work was being performed above live parts. Eighteen near miss situations were classified in the medium-serious B category. They were associated with electrical safety, personal boom lifts, work-related travel, conductor mounting, falling objects, harmful substances, and process separations at reserve power plants.

Important safety toolbox talks and risk assessment days

Safety toolbox talks were implemented at Fingrid in 2015. The requirement to hold them regularly at Fingrid worksites was added to the contract terms concerning safety in 2017. The number of toolbox talks has increased every year, and more than 500 were held at Fingrid worksites in 2018. A toolbox talk is a short event of approximately 15 minutes dealing with current occupational safety matters. A toolbox talk can be given by, for example, a supervisor, the person responsible for the worksite, another person appointed by the main contractor, or a client representative. The goal of toolbox talks is to improve occupational safety knowledge and attitudes and to ensure that all employees are informed of matters such as worksite risk factors, changes in occupational safety rules, and accidents and dangerous situations that have occurred earlier.

Occupational safety work has to be proactive in order for us to achieve the 0-accident target. Risks and hazardous factors must be identified in advance so that people can prepare for and prevent accidents. In 2018, Fingrid held a risk assessment day for many investment projects and at every transmission line and substation basic maintenance work area. The aim of a risk assessment day is to improve the participants’ awareness of risks and identify the jobs and work locations that involve a special risk and for which the supplier performs risk assessments. The day also involves practicing how to perform risk assessments for work.

At Fingrid worksites, the main contractor is responsible for planning occupational safety and for daily monitoring, while Fingrid ensures that the occupational safety requirements are fulfilled. In 2018, Fingrid conducted several responsibility audits and management reviews. In addition, visits to assure occupational safety were made by safety coordinators, local supervisors, regional managers and safety experts.

The outstanding occupational safety results achieved in 2018 were the result of close cooperation between Fingrid and suppliers. In 2018, occupational safety was developed together with the suppliers during, for example, an occupational safety seminar held at the beginning of the year, a management occupational safety discussion held in conjunction with the asset management development days, the suppliers’ occupational safety group, safety supervisor meeting, project kick-off meetings, and worksite meetings. Safety culture is built together with suppliers, and achieving the 0-accident target requires every person’s genuine commitment to the development and maintenance of occupational safety. Occupational safety is all about attitude!