Maintenance Manager Jari Helander says that, for example, the prices of different sensors have dropped so much recently that it’s now a pleasure to search for diverse information about device operation. According to Helander, nearly any variable can be measured regardless of whether it involves the current used, time or trendy-like behaviour.

“For example, slowness or rigidity in the system is visible immediately. The system sets off an alarm if a certain limit value is exceeded,” explains Helander.

“Our goal is to have zero outages because of service,” confirms Helander.

More dynamic data

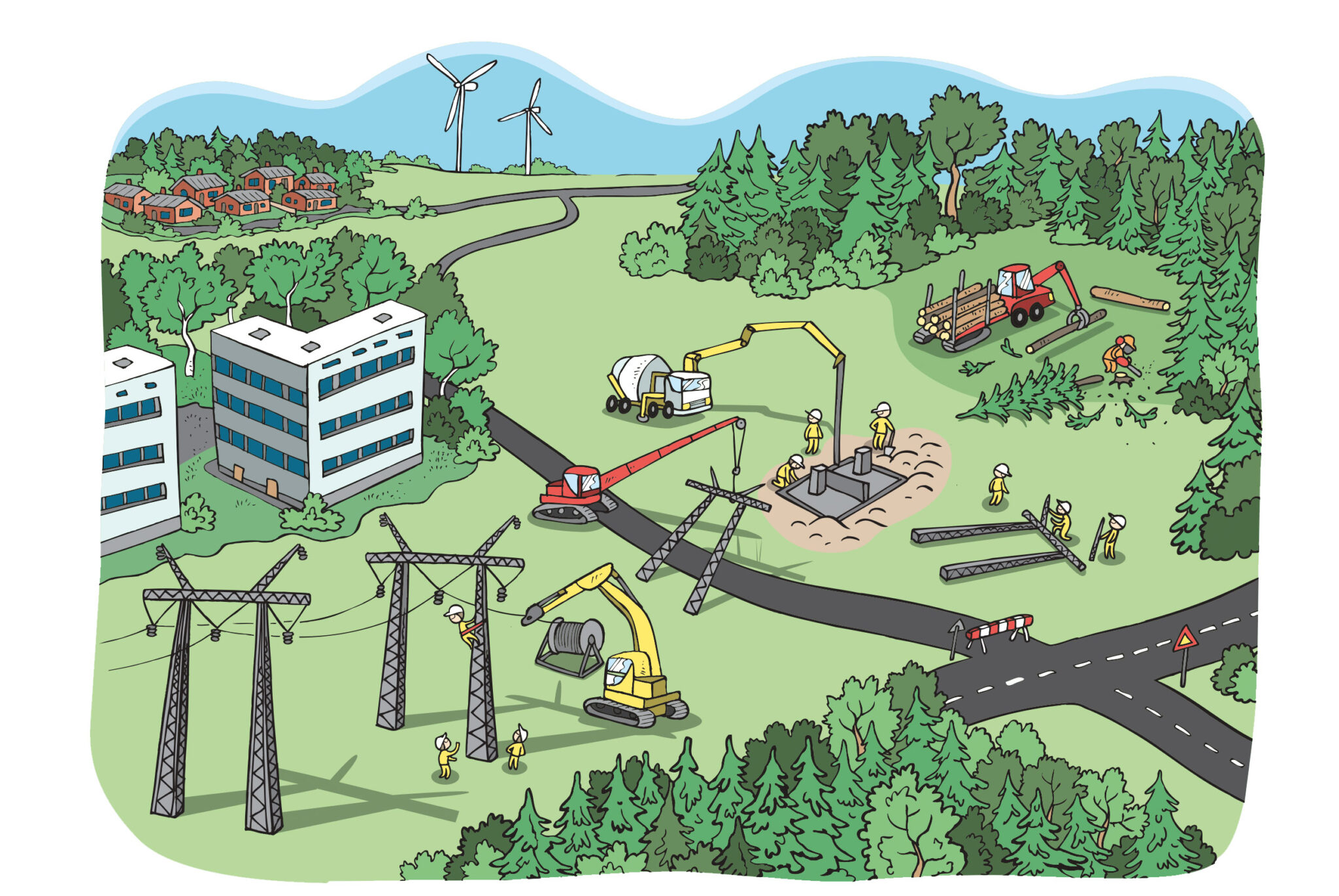

The new Gas Insulated Substations (GIS) have a role of their own. A GIS is smaller and more compact than previous generations, making operations even smoother than earlier.

“We’re now getting completely new digital substations and old stations are being updated all the time,” states Helander. He explains that the digital leap is a big one as the “change the seals and add oil” work is gradually being replaced by data manager tasks.

“For us, this is a major change that also affects people’s competence requirements and the service provider side as well. This is the future that we’re working towards.”

Planting the seeds of innovation

Fingrid also had the future in mind last year when it organised an open idea competition for new development ideas to improve and develop main grid maintenance work and fault repairs. A total of 36 suggestions were submitted in the competition; in the first phase, the ten best ideas were selected for further examination and development. An expert panel eventually selected four finalists.

The top four were Empower’s smart glasses for maintenance work, an acoustic camera from Noiseless Acoustics, Scoopshot’s crowdsourcing-based imaging concept, and Vaisala’s new measurement technology for detecting faults. According to Helander, the acoustic camera has been particularly useful in practice. The acoustic camera detects and locates exceptional sounds. The idea is based on a new kind of acoustic camera technology, which enables the location of equipment faults, for example.

“We’ve purchased 12 Noiseless Acoustics cameras and will begin using them this autumn. The acoustic camera has extremely effective microphones that can pick up sounds at very different frequencies. This provides immediate benefits: when a device or part of it is breaking down, it usually begins to emit an abnormal sound. The acoustic camera has already been tested in the field, and has located faults in a very efficient manner,” says Helander.

Competitive bidding in progress

Other changes in maintenance include a new 3-year cycle for basic maintenance agreements. The old agreements are expiring, so Fingrid is arranging competitive bidding for subcontractors by work area for a new 3-year contract period. The agreements are worth about 20 million euros.

In terms of selection criteria, quality accounts for 25 percent and price for 75 percent.

“We aren’t automatically looking for the cheapest bid, but for the best overall package,” states Helander. The bidders also have to be a member of Fingrid’s supplier register.

Competitive bidding for special maintenance will be arranged separately. •