Fingrid’s transmission grid consists of more than 100 substations with air-insulated substations, circuit breakers and gas-insulated switchgear. Although advancements have been made in electrotechnical equipment in recent decades, one thing remains constant: sulphur hexafluoride gas (better known by its chemical formula, SF6), which functions as a dielectric medium and arc quenching medium in circuit breakers.

Specialist Juhani Tammi explains that SF6 became the dominant circuit-breaking technology in the early 1980s, having enabled the first high-voltage gas-insulated switchgear (GIS) to be developed back in the 1960s. According to Tammi, there are several important factors behind SF6’s dominance.

“SF6 is three times more effective than air as an electrical insulator. Switchgear insulated with SF6 takes up less space, is less prone to faults and requires less maintenance than corresponding components in outdoor switching stations. SF6 is an effective and permanent dielectric gas that also extinguishes arcs in circuit-breakers.”

In the gaseous state, sulphur hexafluoride is invisible, odourless, non-combustible and non-toxic. It is also heavier than air, so it displaces oxygen.

Safely inside equipment

As the climate change debate intensifies, SF6 has risen up the agenda. Fingrid’s Environmental Specialist, Jenni-Julia Saikkonen, explains why.

“SF6 is approximately 23,500 times more potent as a greenhouse gas than carbon dioxide (CO2). This is not a problem as long as the gas remains inside the equipment and the amount escaping into the atmosphere is minimised.”

The European Union’s F-gas Regulation governs the processing of SF6 gas, setting limits for monitoring leaks and qualification requirements for gas handling. Tammi emphasises that Fingrid constantly controls and monitors its use of SF6.

“All of our GIS is within the scope of online monitoring, as are 60 per cent of our outdoor circuit breakers. We monitor possible leaks and take immediate action if any are found.”

GIS typically contains hundreds or thousands of kilograms of SF6 gas. The quantity is much lower in circuit-breakers in outdoor switching stations at 5–30 kg per circuit breaker. In total, Fingrid has 46,000 kg of SF6 gas in various pieces of equipment.

Emissions have remained low

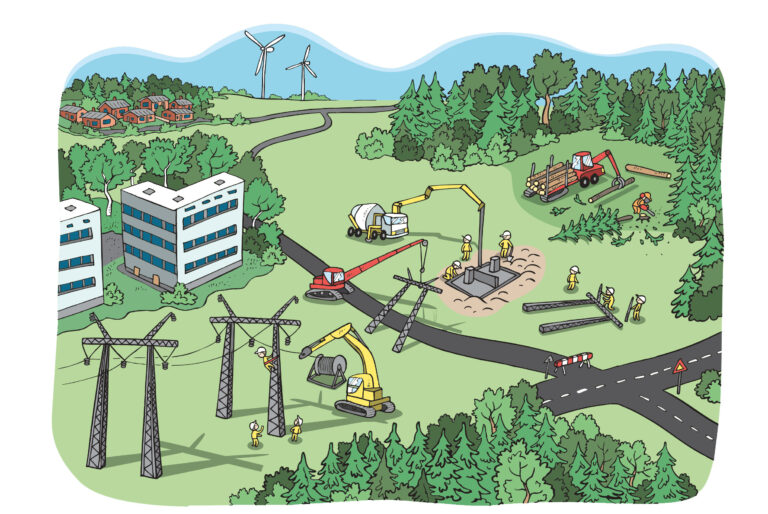

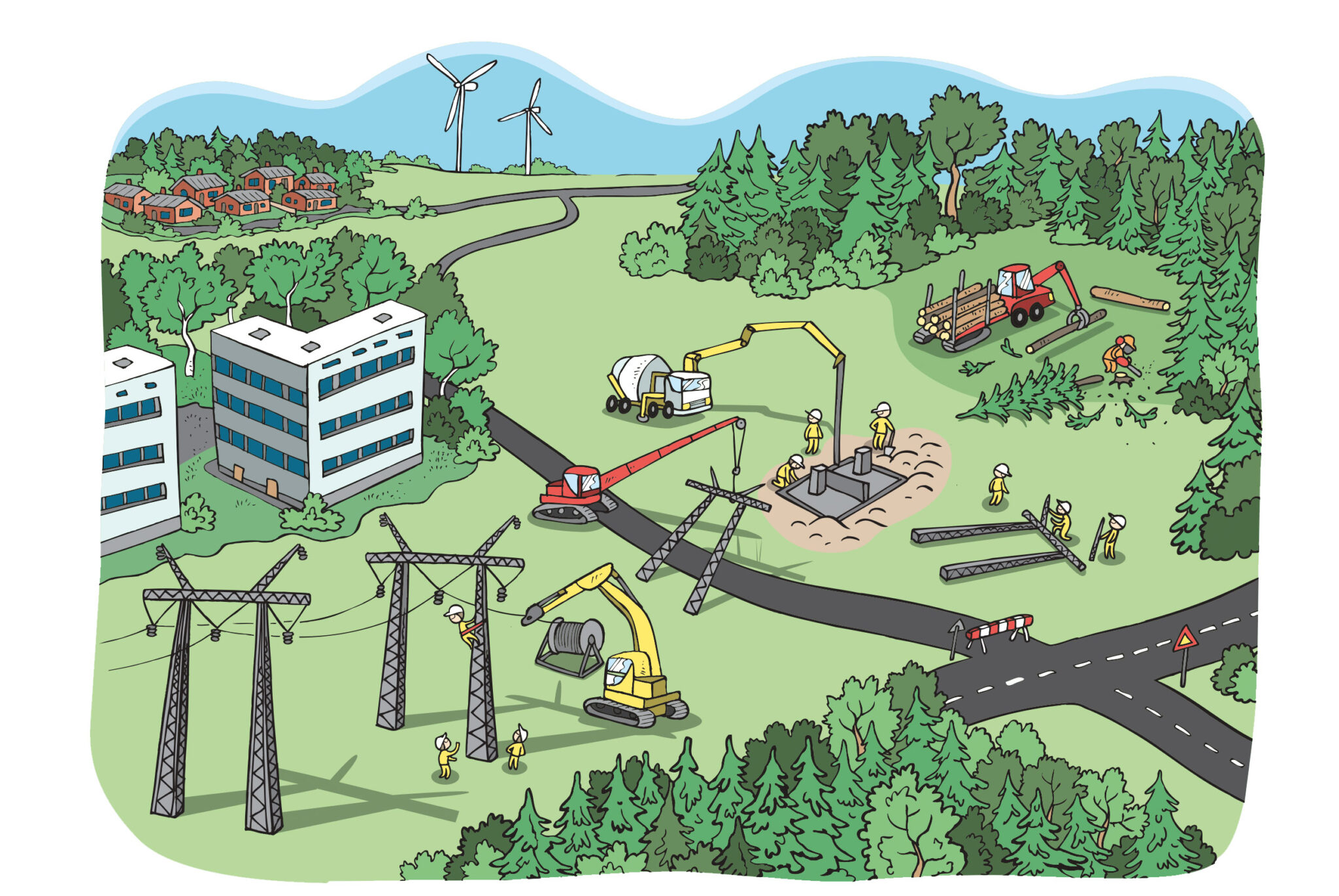

The quantity of SF6 in use has risen constantly, as Fingrid has modernised old sections of the network and built new parts to enable the energy transition. The integration of wind power is currently strongly on the agenda. As regards emissions, Saikkonen is able to present lower figures.

“Equipment containing SF6 continuously experiences very minor leakages of 0.1–0.2 per cent per year.”

In 2018, Fingrid’s SF6 emissions were 494 tonnes of carbon dioxide equivalent (CO2eq). In absolute quantities, this amounted to approximately 21 kg of gas. Fingrid reports to Finnish Energy on its use of SF6 gas.

SF6 does not constitute a major part of Fingrid’s carbon footprint. The greatest impact is made by transmission losses, which gave rise to emissions of 200,400 CO2eq in 2018.

A Europe-wide solution

In the European Union, emissions of SF6 gas are equivalent to 6.73 million tonnes of carbon dioxide, which is about 0.15 per cent of total emissions. GIS is manufactured by three large companies in Europe, which, according to Tammi, are alive to the situation.

“The manufacturers have taken the initiative to develop new insulating technology. Growing pressure from the industry and the EU has served to accelerate this development.”

Fingrid is following developments closely, analysing the alternatives and preparing to pilot new solutions, beginning with the 110-kilovolt network. All of the manufacturers have already launched solutions based on alternative dielectric gases for voltages up to 110 kilovolts. However, none of the new solutions are ready for large-scale adoption because they do not yet meet all of the technical requirements and they lack maturity.

In any case, the transition to a new dielectric technology will take a long time. The estimated service life of switchgear is 40–50 years, and as the dielectric gas in the equipment cannot be changed, it will be decades before new technologies begin to gain traction on the network.