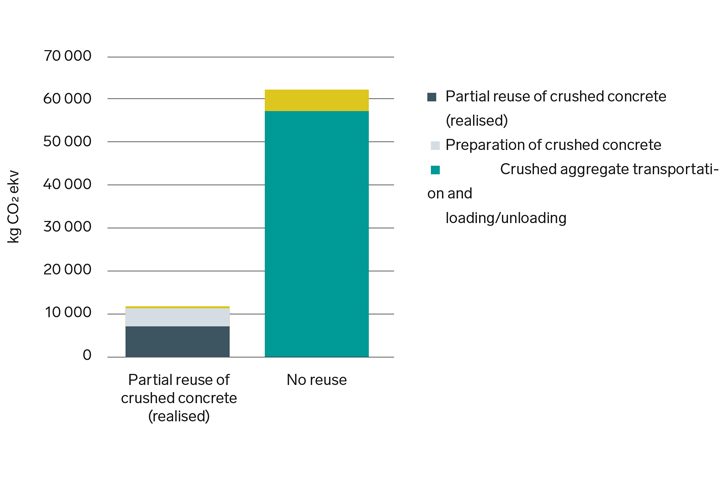

“We use demolished concrete and brick waste in our substation projects, so we need to have a clear understanding of the environmental impacts of these materials, as well as the means of minimising the negative impacts,” says Maija Nurmi, Environment, Health and Safety Specialist at Fingrid.

Suvi Ollikainen’s thesis focused on the official permit procedures required in order to make use of concrete and brick waste, as well as the use of demolition waste in terms of costs and carbon dioxide emissions.

“Real-world figures on greenhouse gas emissions and actual monetary costs help when deciding whether it is possible to use concrete in various investment projects,” Nurmi states.

The research confirmed that it is almost always worth replacing natural aggregate with crushed concrete by both metrics and that the permit procedures related to utilising these materials vary greatly from one municipality to the next.

The research confirmed that it is almost always worth replacing natural aggregate with crushed concrete.

“Naturally, we will be happy to share our experiences, best practices, and the lessons learned from this thesis with our stakeholders. For example, we now have access to some clear formulas for calculating the profitability of reusing concrete in future projects,” Nurmi says.

In Finland, 80 million tonnes of mineral aggregate is used for earthwork every year.

Waste-based materials that are suitable for earthwork are produced in almost the same quantity. Crushed concrete has been reused for earthwork since the start of the 1990s.

“In many of its technical properties, crushed concrete is just as good as mineral aggregate, and its load resistance is even better than natural stone,” Ollikainen says.

“Favouring reused materials is one way of promoting material efficiency and the sustainable use of natural resources. It also reduces the negative environmental impacts of construction projects. Efforts have been made to promote the use of recovered materials in earthworks with the help of legislation and various studies.”

Additional information

Maija Nurmi

maija.nurmi@fingrid.fi