Jukka Roponen, Project Manager at TMV Service, takes care of safety on several of Fingrid’s construction sites. Assessing the risks before embarking on a construction project is the key to avoiding accidents.

“When all the risks can be identified in advance, we can respond to them and no accidents happen. Risk assessment is the basis of occupational safety, so it is a very important job on the worksite,” he emphasises.

“Risk assessment is the basis of occupational safety, so it is a very important job on the worksite.”

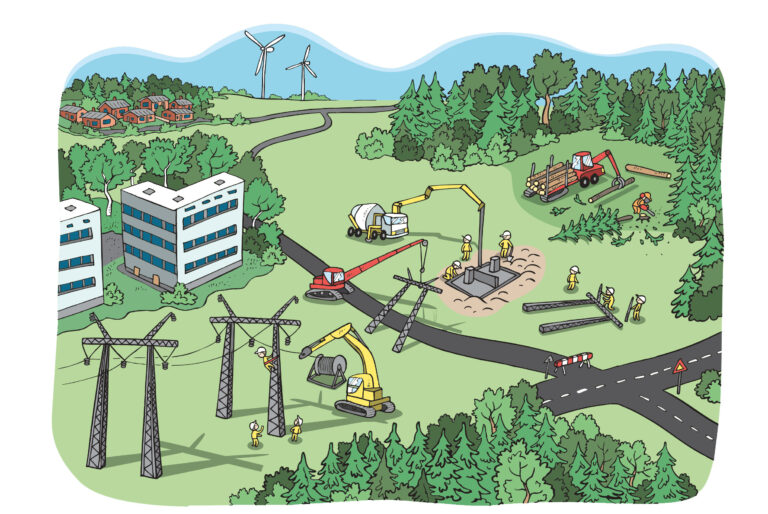

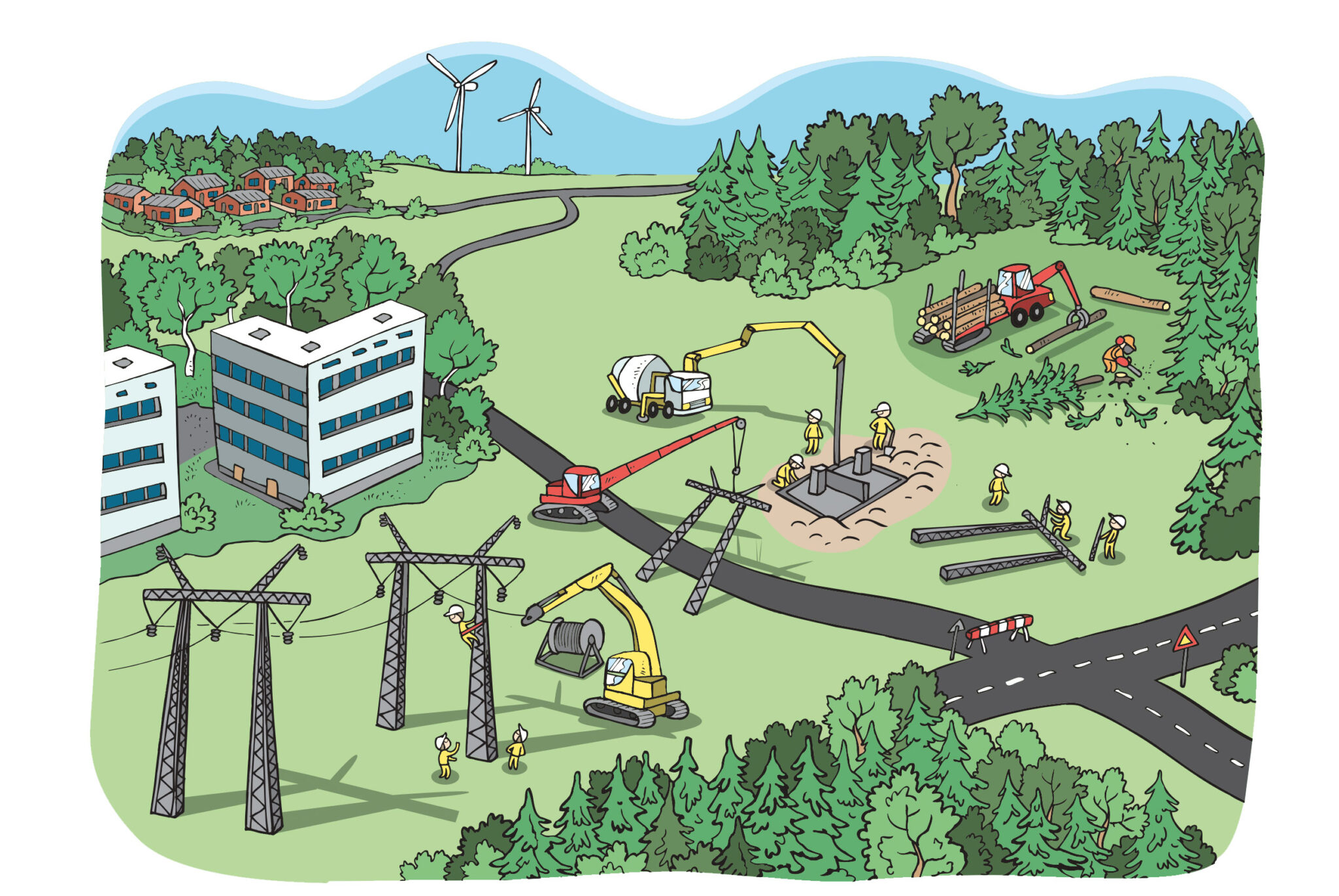

At present, Roponen has worksites in Alajärvi, Palojärvi, Heinola and Rauma. The same important actions are taken on every worksite to ensure occupational safety.

Everyone working on the project is involved in the risk assessment, from supervisors to technicians. Subcontractors should analyse the risks of their work.

“Risk assessments are visible on our intranet, and they are sent out to every relevant party, including Fingrid, in the same way as work plans.”

Three levels of risk assessment

Roponen says that risks are assessed in three phases. The first step is to assess the risks of the project as a whole. This is a wide-ranging, top-level process.

“It involves reviewing the risks in general terms. These may include, for example, the risks inherent in construction, foundation work and excavation.”

In the second phase, the risks of the specific worksite are assessed: the parties review the plans for the work and think about the work phases in more detail.

“At this stage, we are already delving deep into the work itself, describing the working methods in

detail. This may include lifting plans, risk assessments for lifting work and fall prevention plans.”

The third phase is completed before starting the work, when employees assess the risks within their groups.

Technicians participate in weighing up the risks before they go to their work locations. When they reach the site, they discuss any hazards with the worksite manager. Employees also add their comments to the risk assessment.

“When people arrive at the work location, they may notice something that is not right. For example, the ramps leading to an excavated pit may be too steep, the planned access route may not be safe, or there may be items or rubbish in the work location that make it dangerous to move around the area,” Roponen says.

Risks are under constant consideration on worksites

Risk assessment is not limited to the three phases; it is carried out constantly as work progresses.

When new work tasks begin, new risks sometimes arise, and risk management is enhanced by taking the new risks into consideration.

“If we identify a hazard that could recur or arise elsewhere, it will be included in project-specific risk management in the future.”

Near misses are always recorded in the Quentic system so they can be analysed in more depth. Near misses are also discussed on worksites.

Roponen commends Fingrid’s commitment to occupational safety and its encouragement of risk assessment.

“Electricians learn the risks of their trade when they complete their vocational education and people are well aware of the dangers of working at height. Nonetheless, Fingrid’s sparring and encouragement have helped us to carry out better risk assessments.”

Fingrid’s campaign, entitled Occupational Safety is Created by Individuals and Teams, has appeared on worksites over the spring and summer.

“Worksite managers have held safety toolbox talks on the campaign themes, and the posters have been displayed.”