Concrete and steel are the largest material types produced at Fingrid worksites. They aren’t necessarily waste, because nearly all the material can be used again,” explains Environmental Specialist Maija Nurmi from Fingrid.

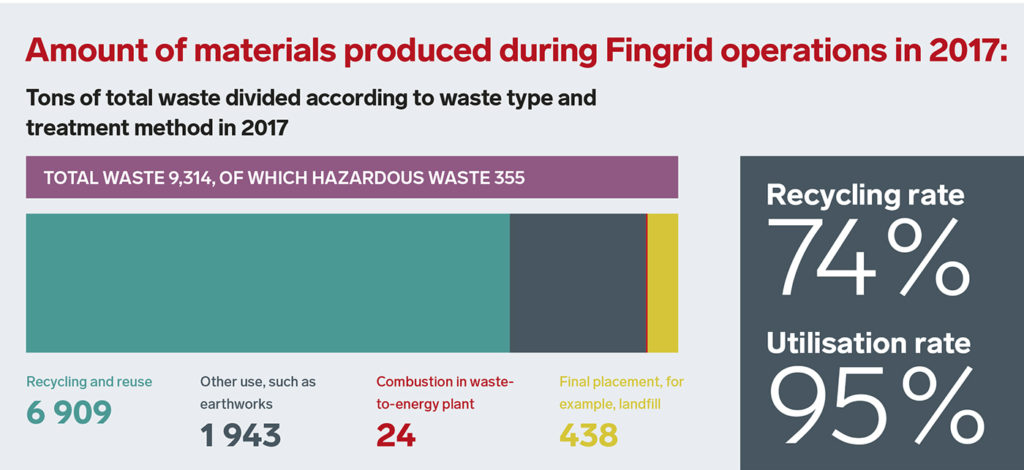

In 2017, 9,314 tons of different materials were collected at worksites, and 6,919 tons of that amount was recycled and reused. A total of 1,943 tons was used in other ways, for example, in earthworks. Concrete is typically used in the foundation structures of roads, fields or industrial buildings.

“Metal is particularly easy to recycle because there is always demand for it. The rate of recycling for metals is nearly 100%. Our service provider delivers metal for further processing and from there to different places according to the market situation.”

So-called construction waste – the mixed waste produced during construction work – is problematic in terms of recycling. Construction waste consists of mixed materials from demolition worksites that cannot be recycled. Most of this waste is produced during substation construction and dismantling work.

Effective sorting at worksites

Logistics plays an important role in all recycling activities. It’s essential to optimise and carry full loads in order to make transportation cost-effective and minimise emissions.

Proper sorting at the worksite is also extremely important.

“Our construction contractors have a good understanding of how important this is, and the loads leaving our worksites are mostly very well sorted and loaded,” says Nurmi.

Material recycling at Fingrid worksites is handled by the same service provider throughout the country. One of main focuses when selecting the provider was a comprehensive and advanced operating method.

“We require electronic ordering and reporting from our service provider. This gives us access to reliable statistics about material amounts and sorting. We also pay a lot of attention to forecasting order needs. Better forecasting of orders means more efficient transports.”

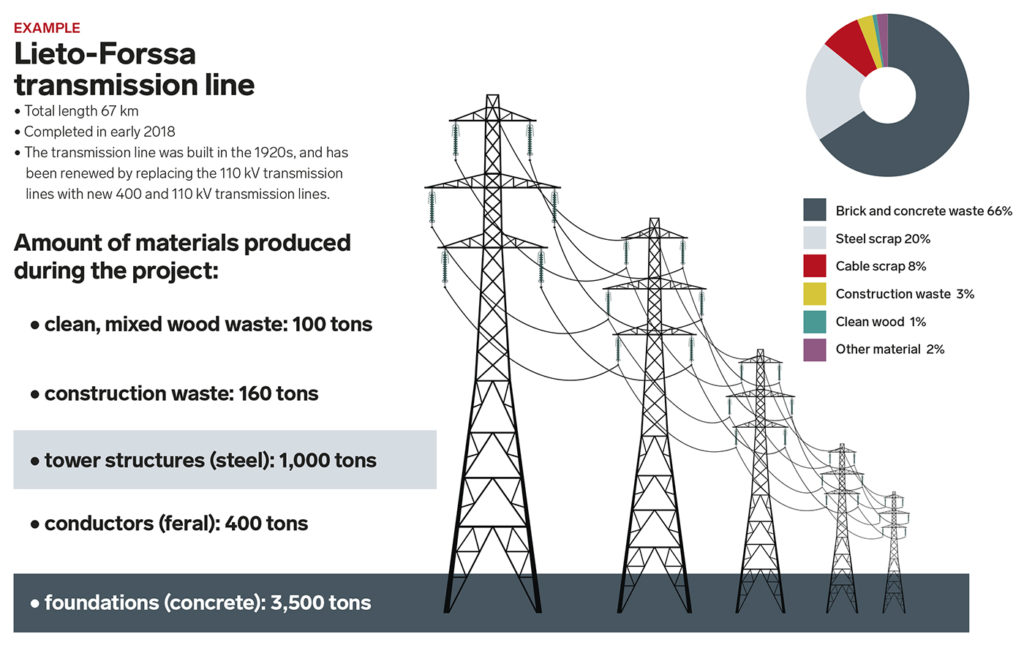

- All concrete was delivered to the Kiimassuo waste treatment centre located near the worksite, where it was used in the centre’s own infrastructure construction.

- All metals (steel and feral) went to a treatment plant in Karjaa, where the metals were processed as efficiently as possible into recycled raw material for industry. The recycling rate for metals is 100%, and 90% of the metals are exported.