In 2020, there was a total of 16 lost time injuries five of which were severe accidents. We categorise an accident as severe if it causes the employee to be on sick leave for more than 30 days or if it results in a permanent disability or bodily injury. A total of 28 recorded injuries occurred (16 leading to absences, 10 requiring medical treatment, and two necessitating restricted work). Most of the lost time injuries in 2020 were slips and trips. One factor that the accidents have in common is the working environment – several of the accidents occurred while working in the field (transmission line projects and maintenance, as well as vegetation management). However, several accidents have occurred recently in very different lines of work, affecting many different suppliers.

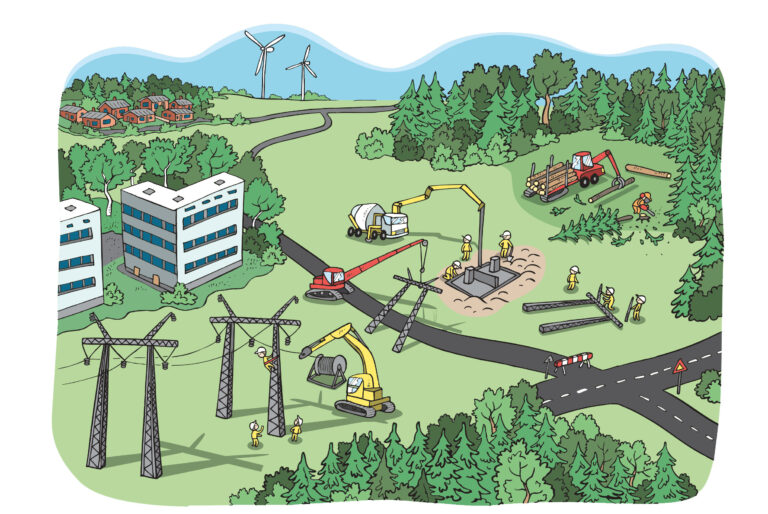

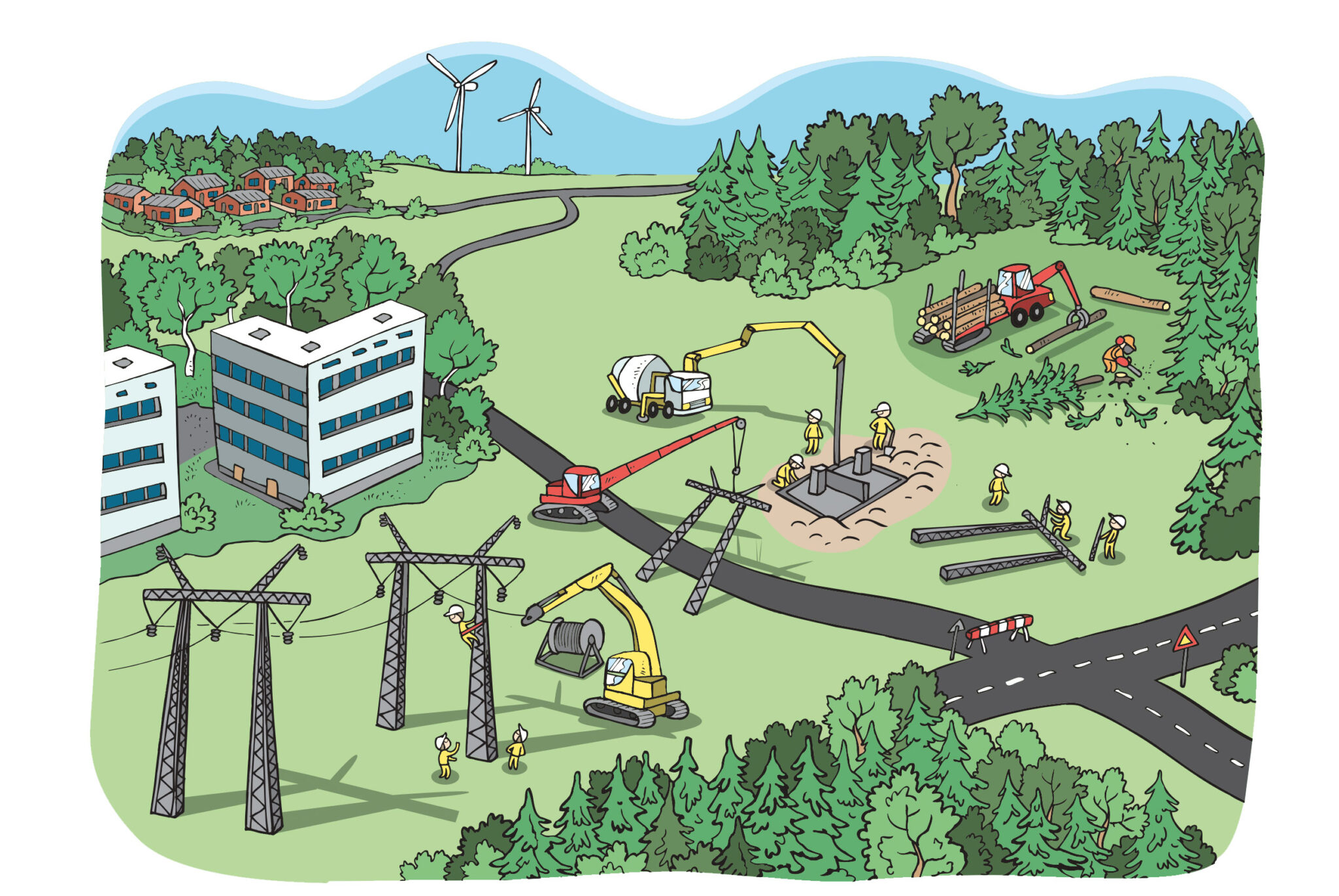

Two severe accidents occurred in transmission line projects. One was the result of an employee slipping after stepping onto an icy steel structure. The other occurred when a conductor wheel fell onto an employee’s hand while the employee was moving it manually. A severe occupational accident occurred on a transmission line maintenance project when an employee was in a ditch, fixing a lifting chain around a wooden pole and it rolled onto the employee’s leg. A severe occupational accident occurred during maintenance work at a reserve power plant when a hydraulic jack slipped and struck the employee on the head. An employee engaged in vegetation management work suffered a severe occupational accident when a clearing saw made contact with the employee’s finger. In addition, two more occupational accidents occurred that did not lead to absences but are nonetheless classified in the most severe category (category A) due to the potential consequences. On a substation project, an employee sustained a gash in the thigh due to the recoil of a diamond saw, and on a reserve power plant refurbishment project, an employee sustained an electric shock from a fluorescent light.

There were two severe, category A near-misses in 2020. During a test loading of a beam hoist on a substation project, the extension beam gave way, and the shuttle car and the load it was carrying fell to the ground. In addition, during measurement maintenance work on a disconnecting circuit breaker, an induced voltage burnt the measuring device. In addition to these, there were approximately 30 near-misses of moderate severity (category B), which is more than in the previous years. Among the causes of hazards were a load falling down during a lift, a vehicle sliding off the road, electrical/work machinery making contact with live cables and overhead lines, falling objects, the accelerator of a quad bike becoming stuck, a support falling over while the support’s leg was being replaced, and fuel being discharged into a tank without permission at a reserve power plant.

The number of safety observations did not quite reach the target of 600. However, there was a sprint finish in the autumn when a pleasing number of observations were submitted during the safety observation campaign. Approximately 500 safety observations were made in 2020. We discuss the safety observations elsewhere in this magazine. More safety toolbox talks are being reported year after year, and the total number has increased tenfold in about five years. Fingrid’s suppliers are to be commended for this. In 2020, the goal was to receive at least 600 safety toolbox talk reports. In the event, more than 700 safety toolbox talks were reported, so this target was surpassed with ease. The safety toolbox talks have become an integral part of our suppliers’ activities, and they cover accidents and near-misses that have occurred, safety toolbox talk materials prepared by Fingrid and the suppliers themselves, and relevant occupational safety topics.

We worked on many fronts to enhance occupational safety in 2020. In May 2020, Fingrid’s Executive Management Group approved Fingrid’s pledge on occupational health and safety methods and targets. We held an occupational safety workshop for Fingrid’s Executive Management Group. We updated the occupational safety handbook related to our occupational health and safety management system, and we expanded the scope of the system.

In 2019, Fingrid initiated a project called the Crystal-Clear Line with the aim of clarifying the occupational safety responsibilities of Fingrid and its suppliers. One practical measure was the redrafting of the contract terms. The new contract terms concerning safety took effect on 1 January 2020. In 2020, we arranged a total of eight training events concerning the new contract terms for the personnel of Fingrid and its suppliers. We also updated Fingrid’s online training to address the new contract terms. Detailed requirements were removed from the contract terms and transferred to the material on good practices. We also arranged training for suppliers and Fingrid’s personnel on the good practices material. Training in good occupational safety practices will continue in 2021.